You’ve likely heard the term EMI or electromagnetic interference if you’ve ever worked with electronics or communications systems. But what does it actually mean, and why should we care? At its core, EMI refers to the disruption or disturbance that electromagnetic fields can cause to electrical circuits and devices. And as our world becomes more interconnected with technology, understanding why EMI is used and how it’s managed is becoming increasingly crucial.

EMI occurs naturally—thanks to things like lightning, solar radiation, or even electrical storms. But it also arises from the countless electronic devices we use in our everyday lives, from our smartphones to microwave ovens, all the way to the complex equipment used in industries like aerospace, automotive, and telecommunications.

For engineers and product designers, EMI management is no trivial matter. If EMI isn’t effectively controlled, it can compromise the functionality, safety, and reliability of electronic systems, sometimes even rendering them inoperable. That’s why understanding why EMI is used in engineering contexts—and how to manage it—can be the difference between a successful product and one that fails to meet safety and performance standards.

Electromagnetic Interference (EMI) refers to the unwanted electrical noise that interferes with the operation of electrical circuits. This can happen when electromagnetic waves from one source disrupt the signals being transmitted by another nearby device or circuit. These interferences can cause devices to malfunction, disrupt signal transmission, or even damage sensitive components.

In simple terms, EMI is like someone shouting over a conversation—making it hard for you to hear the important signal or information.

There are two types of EMI:

- Conducted EMI – This occurs when interference travels through conductive materials like wires or cables. It’s essentially a ‘leak’ of electrical noise through the physical connections of a device.

- Radiated EMI – This type of interference occurs when electromagnetic waves spread out from a device and interfere with nearby equipment. It’s akin to someone broadcasting unwanted noise into the air.

EMI can occur from various sources, including:

- Natural sources: Lightning strikes, solar flares, and cosmic rays.

- Man-made sources: Household electronics like computers, power lines, radios, and even microwaves. Imagine how your phone signal might drop when you walk by a large refrigerator or a poorly-shielded electrical device—that’s EMI at work.

How Does EMI Occur?

Now that we know what EMI is, let’s explore how it occurs. The underlying cause of EMI lies in the interaction of electromagnetic fields, which are present in all electrical devices.

Here’s the breakdown:

- Electric fields: These are generated by voltage differences (think of the static electricity you feel when touching a metal object). When voltages fluctuate rapidly or erratically, they can send out electric fields that affect surrounding components.

- Magnetic fields: These are generated by the flow of electric current through conductors. The faster the current changes, the stronger the magnetic fields can become, potentially interfering with other signals.

When both electric and magnetic fields are generated simultaneously, they propagate through space and can couple with nearby circuits, leading to EMI.

The Role of EMI in Modern Technology

EMI plays a significant role in many areas of technology. It’s not just about interference; it’s about how engineers design and develop products to function safely and reliably in an increasingly electronic world. Let’s explore why EMI is used or more accurately, how EMI is managed in different sectors.

EMI in Communication Systems

In communication systems—whether for radios, televisions, mobile phones, or Wi-Fi networks—EMI is both a concern and a challenge. Communication devices operate by sending and receiving electromagnetic signals, and EMI can disrupt those signals. A mobile phone, for instance, operates in the GHz (gigahertz) frequency range, where EMI can easily cause data corruption, dropped calls, or poor signal reception.

To combat this, communication devices and transmission equipment undergo rigorous EMI testing to ensure they meet certain standards and don’t emit harmful levels of interference. EMI shielding and filters are implemented to minimize the impact of external interference and ensure signal integrity.

EMI in Medical Equipment

In the healthcare sector, particularly in medical devices like pacemakers, MRI machines, and ventilators, EMI is a serious issue. These devices must function in environments where electromagnetic fields from other devices (such as mobile phones or nearby electrical equipment) could compromise their performance.

For example, a pacemaker that’s not properly shielded from EMI could malfunction, leading to severe health risks. This is why EMI shielding in medical equipment is absolutely critical for ensuring safety and reliability.

EMI in Automotive Systems

As cars become more connected and automated, the number of electrical components in them grows. Modern vehicles are full of electronic systems that control everything from engine performance to navigation and safety features like airbags and automatic braking systems. EMI can interfere with these sensitive components, causing malfunctions or failures in key systems.

To address this, automotive engineers use EMI shielding and grounding techniques to protect critical systems from interference. Moreover, with the advent of electric vehicles (EVs) and autonomous driving technologies, minimizing EMI has become even more crucial for the safe operation of these systems.

EMI in Aerospace and Defense

In the aerospace and defense industries, EMI is more than just a nuisance; it’s a matter of national security. Communication systems on military aircraft, spacecraft, and satellites must be highly resistant to EMI, as even a minor disruption can result in catastrophic failures. For instance, a misfiring missile or the loss of radar communication could be disastrous in defense operations.

To mitigate this risk, aerospace engineers use advanced EMI shielding, high-performance filters, and rigorous testing protocols to ensure the reliability of their systems under a variety of environmental conditions.

The Role of EMI Shielding and Controls in Managing Interference

Now that we have a solid grasp of what EMI is and why it’s used, let’s dive deeper into how EMI is controlled and why it’s an essential part of any product design or system maintenance. EMI shielding, filtering, and grounding are the primary techniques used to manage and reduce interference.

These methods help to ensure that devices perform optimally, meet safety standards, and function reliably in complex electromagnetic environments. But why exactly is it necessary to go through all this trouble? Let’s break it down.

EMI Shielding Techniques

EMI shielding refers to the practice of blocking or reducing the electromagnetic waves that cause interference. It’s like building a fortress around sensitive equipment to protect it from external electromagnetic disruptions. Here are some common techniques used to shield against EMI:

- Metallic Shields

Metallic shielding materials like aluminum, copper, and steel are often used because they can reflect or absorb electromagnetic waves. When electromagnetic interference (EMI) encounters these materials, it either gets absorbed or reflected, preventing it from penetrating sensitive components. This type of shielding is particularly effective for devices that need to operate in high-interference environments.- Advantages: High attenuation of EMI, cost-effective for mass production, durable.

- Challenges: Can be heavy, bulky, and costly to integrate into compact designs.

- Conductive Coatings and Platings

For devices that cannot be shielded with metal casings (like plastic enclosures), conductive coatings can be applied to the surface to reduce EMI. Materials such as silver or copper-based conductive coatings can turn non-metallic surfaces into effective shields. These coatings are thin, lightweight, and often used for consumer electronics.- Advantages: Lightweight, cost-effective, and applicable to various substrates.

- Challenges: May not offer as much protection as metal shields, requires precise application.

- Gaskets and Seals

EMI gaskets and seals are used to fill gaps or seams in enclosures to prevent the leakage of electromagnetic waves. These gaskets are typically made from conductive rubber or foam that conforms to the shape of the enclosure, ensuring that electromagnetic waves cannot slip through any small openings.- Advantages: Effective for sealing complex enclosures, easy to integrate in design.

- Challenges: Could wear out over time, requires regular checks to ensure integrity.

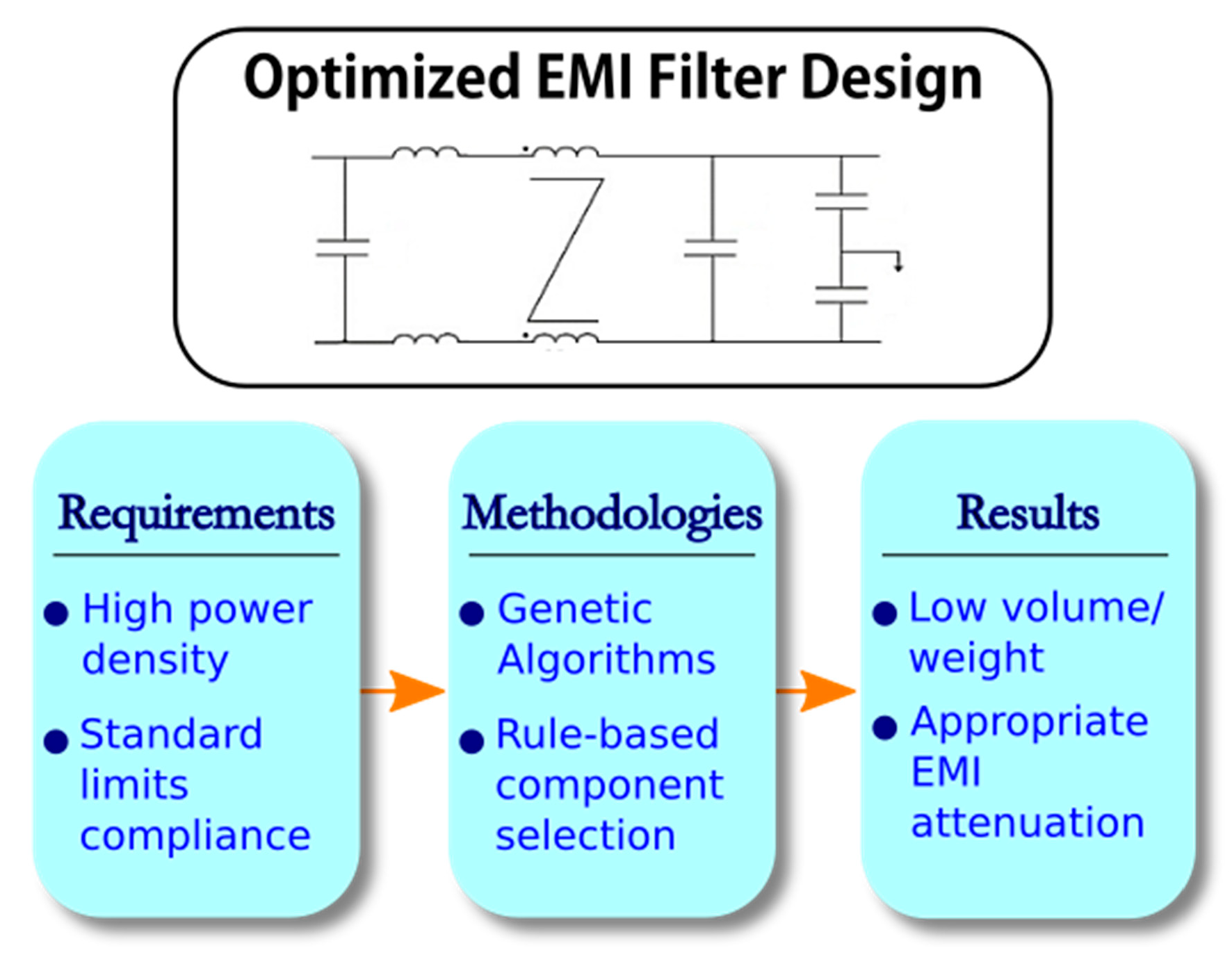

EMI Filtering and Grounding Techniques

EMI filters are designed to prevent conducted EMI from entering or leaving a device via power or signal lines. These filters act as ‘gatekeepers’ that allow the necessary signals to pass through while blocking unwanted electromagnetic noise. Filters come in various types, such as low-pass filters (which allow low-frequency signals to pass through while blocking high-frequency noise), and band-pass filters (which allow signals within a specific frequency range to pass).

Grounding is another important technique. By grounding electrical circuits properly, engineers can provide a direct path for the flow of unwanted electrical currents, helping to dissipate the EMI energy safely. Poor grounding can lead to increased noise levels, affecting the performance of electronic components.

- Advantages: Easy to implement, cost-effective, and effective at controlling conducted EMI.

- Challenges: Complex devices may require sophisticated filtering systems.

PCB Design Strategies for Minimizing EMI

One of the most critical areas of EMI management in modern electronics is Printed Circuit Board (PCB) design. PCBs are the backbone of almost all modern electronics, from smartphones to medical devices. The layout and design of a PCB can either enhance or worsen its susceptibility to EMI. Here are some strategies used to minimize EMI in PCB designs:

- Shielded Traces

PCB designers often use shielded traces or ground planes to contain and control the flow of signals and reduce the impact of radiated EMI. A ground plane is a layer of copper that covers a large area of the PCB, providing a continuous ground path for signals. This can significantly reduce noise in sensitive areas of the circuit. - Component Placement

Where you place components on a PCB matters. Designers typically place high-frequency components away from sensitive analog sections to minimize EMI coupling. Components like oscillators, which generate high-frequency signals, should be isolated from other sections of the board. - Use of EMI-Rated Components

Certain components, such as EMI-resistant capacitors or inductors, are specially designed to minimize interference. These components are crucial when designing high-speed circuits and ensuring that they don’t radiate unwanted electromagnetic waves.- Advantages: Improved performance, better signal integrity, fewer system failures due to EMI.

- Challenges: Can increase complexity and cost of PCB design.

EMI Testing and Standards

After all the shielding and filtering methods are implemented, the next step is ensuring that the product performs as expected in real-world conditions. EMI testing is used to measure the levels of electromagnetic interference emitted by a device and to check its EMC (Electromagnetic Compatibility). In many industries, particularly healthcare, aerospace, and telecommunications, devices must meet specific EMI compliance standards set by regulatory bodies.

For instance:

- FCC (Federal Communications Commission) in the U.S. regulates EMI emissions for consumer electronics.

- CE (Conformité Européenne) marking is required for products sold in Europe, indicating they meet electromagnetic compatibility standards.

EMI testing can be done through radiated emissions testing (measuring the electromagnetic fields radiated from a device) or conducted emissions testing (measuring the noise transmitted via power and signal lines).

Testing not only ensures that a product is safe and reliable, but it also helps prevent expensive recalls or regulatory fines that could arise from non-compliance.

Why EMI Is Used and How It Shapes the Future of Electronics

As we’ve seen, EMI is an inherent part of modern technology, affecting everything from communication systems to medical devices and vehicles. However, EMI is not just a nuisance; it is a factor that must be carefully managed through shielding, filtering, grounding, and meticulous PCB design to ensure safe, reliable, and high-performance products.

The methods used to control EMI are continually evolving, with new materials, more efficient shielding techniques, and advanced EMI testing standards pushing the boundaries of what’s possible. As wireless communication, 5G, and IoT (Internet of Things) technologies continue to grow, the importance of EMI management will only increase, making it a fundamental part of every engineering project.

So next time you enjoy a hassle-free phone call or watch your favorite show on a screen without interference, remember that there’s an entire army of engineers working behind the scenes to ensure that EMI doesn’t interfere with your experience. EMI is used, not just to create interference, but to guide designers in crafting products that are safe, reliable, and effective in an increasingly connected world.

Industries and Applications That Rely on EMI Management

Now that we understand the techniques used to control EMI, let’s take a look at the industries and applications where EMI management is not just important but absolutely critical. Whether it’s in consumer electronics, medical devices, automotive systems, or aerospace, each sector relies heavily on effective EMI control to ensure reliability, safety, and performance. Let’s explore a few key sectors in more detail.

EMI in Consumer Electronics

Consumer electronics are one of the most EMI-sensitive industries because almost every home today is packed with devices that emit and receive electromagnetic waves. Think about it: your smartphone, laptop, microwave, TV, and even smart speakers all have to coexist in a single environment without interfering with each other.

To keep devices from malfunctioning due to interference, manufacturers use a variety of EMI shielding techniques, like metallic cases, conductive coatings, and filters. For example, smartphones are designed with specific metallic enclosures that act as EMI shields, preventing interference from wireless signals, powerlines, or other devices.

Here are a few examples of how EMI management plays out in the consumer electronics world:

- Laptops and PCs: EMI shielding prevents interference between high-frequency components (like CPUs) and other peripherals.

- TVs and Monitors: EMI shielding ensures that broadcast signals aren’t distorted by other household appliances.

- Wearable Devices: With the rise of wearables like smartwatches and fitness trackers, EMI shielding ensures that signals like Bluetooth don’t interfere with medical or environmental sensors.

- Challenges: Consumer devices need to be lightweight, affordable, and compact, which means that EMI shielding must be efficient but not overly bulky.

EMI in Healthcare

EMI control in medical devices is a matter of life and death. From heart monitors to pacemakers, the performance of these devices is critical, and interference from external electromagnetic sources could have disastrous consequences.

For example, pacemakers are sensitive to electromagnetic interference from other devices like mobile phones, microwaves, or even microwave ovens. If a pacemaker gets disrupted by EMI, it can cause irregular heartbeats or even failure of the device. That’s why medical equipment manufacturers invest heavily in EMI shielding to prevent such risks.

Some key examples of EMI in healthcare:

- MRI Machines: These devices use powerful magnetic fields and radiofrequency signals, and they must be shielded to prevent EMI from affecting their operation.

- Defibrillators: EMI can interfere with the functioning of defibrillators, which are used to restart a heart during emergencies. Ensuring EMI shielding in such critical devices is non-negotiable.

- Medical Implants: Devices like pacemakers, neurostimulators, and hearing aids need EMI protection to ensure they function properly and do not fail due to interference.

The healthcare industry’s strict regulations around EMI compliance, such as FDA guidelines and ISO standards, ensure that EMI management is consistently upheld to protect patient safety.

- Challenges: Cost and precision—medical devices need to be ultra-precise and often work in environments where EMI sources are abundant (e.g., hospitals with many electronic devices).

EMI in Automotive Systems

Automobiles are becoming more electronic every year. From advanced driver assistance systems (ADAS), to infotainment systems, to electric vehicles (EVs), the number of electronic systems in vehicles has skyrocketed. And while this progress is great, it brings a unique challenge: EMI. A malfunction in critical automotive systems due to EMI could be catastrophic, which is why EMI management in vehicles is taken very seriously.

Examples of EMI in Automotive Systems:

- Advanced Driver Assistance Systems (ADAS): Systems such as automatic braking, lane departure warnings, and collision detection rely on sensors and cameras, which must be shielded from EMI to ensure accurate readings.

- Electric Vehicles (EVs): EVs rely heavily on high-voltage systems for battery charging and powertrains, which can be a significant source of EMI. Ensuring these systems don’t interfere with signal communications is crucial.

- In-Car Entertainment Systems: With the increasing number of entertainment options (streaming, Bluetooth, wireless charging), the systems need to be protected from EMI so passengers don’t experience dropped signals or poor sound quality.

To deal with EMI in automobiles, manufacturers implement shielding materials in high-sensitivity areas and develop robust grounding techniques to ensure signal integrity.

- Challenges: Cost and space constraints—automotive designs are often compact, and adding too much shielding could affect vehicle weight and fuel efficiency. Balancing EMI management with these factors is key.

EMI in Aerospace and Defense

In aerospace and defense, the stakes are even higher. Systems in airplanes, rockets, and military equipment must perform flawlessly, and any interference could be disastrous, especially in mission-critical operations like navigation, communication, or weapons systems. EMI could potentially disrupt radar, GPS, or communication signals, which are essential for both civil aviation and military operations.

Examples of EMI in Aerospace and Defense:

- Aircraft Systems: EMI shielding is used extensively to protect avionics (the electronic systems of an aircraft) from interference that could impact flight control or navigation systems.

- Satellites: Satellites must withstand EMI from external sources (like solar radiation) and must also be shielded to ensure clear communication with ground stations.

- Military Equipment: In the defense sector, advanced weaponry, radar systems, and unmanned aerial vehicles (UAVs) rely on EMI shielding to ensure that the equipment performs in harsh, high-interference environments.

Because EMI could mean the difference between success and failure in aerospace or defense operations, products in these fields undergo stringent EMI testing to meet military and aerospace standards (e.g., MIL-STD-461).

- Challenges: Extreme environments (high altitudes, harsh weather, radiation) require robust shielding that’s often lightweight and resistant to a variety of electromagnetic threats.

Why EMI Testing Is Crucial for Regulatory Compliance

In many industries, EMI testing is not just about quality assurance—it’s about compliance with strict regulations that ensure safety and functionality. For example, FCC regulations in the United States and CE standards in Europe set limits on the amount of electromagnetic radiation that a device can emit.

Why EMI testing matters:

- Ensures safety: Ensures that devices do not emit harmful interference that could affect public health, critical systems, or other electronic devices.

- Meets regulatory standards: Many industries (e.g., healthcare, telecommunications, defense) have stringent EMI and EMC standards. Devices must pass EMI testing to be sold in the market.

- Protects product performance: Effective EMI testing ensures that devices function reliably without failure, even in environments with significant electromagnetic activity.

The Importance of EMI Management in the Future of Electronics

Whether it’s consumer electronics, medical devices, automotive systems, or aerospace applications, EMI management is an essential consideration in every stage of product design, from concept to production to end-use. As our world becomes even more interconnected with wireless communication, IoT, and 5G networks, the importance of managing EMI will only continue to grow.

By understanding why EMI is used and how to control it, engineers and manufacturers can develop products that not only meet safety standards but also deliver reliable performance in a world full of potential electromagnetic disruptions.

So, the next time you’re using a piece of electronic equipment, from your favorite smartwatch to the car you drive, take a moment to appreciate all the behind-the-scenes EMI shielding that’s helping to keep everything running smoothly. Who knew something so invisible could make such a big difference?

Future Trends in EMI Management

As the world becomes more digitally connected and reliant on advanced technology, the management of Electromagnetic Interference (EMI) will continue to evolve. With 5G, Internet of Things (IoT), electric vehicles (EVs), and autonomous systems becoming more widespread, the landscape of EMI management is constantly changing. Let’s explore some of the exciting trends that are shaping the future of EMI control.

Advances in EMI Shielding Materials

Historically, EMI shielding has relied on metals like aluminum, copper, and steel, as well as conductive coatings. But as devices get smaller, lighter, and more powerful, the materials used to shield these devices are evolving to meet new needs.

Here are some innovative materials that are gaining traction in the field of EMI shielding:

- Graphene-based Materials: Graphene, a form of carbon that is just one atom thick, is being explored as an ideal material for EMI shielding. It’s lightweight, flexible, and incredibly conductive, making it a perfect fit for future electronic devices, including wearables and flexible electronics.

- Nanomaterials: Researchers are developing nanomaterials that can be engineered at the molecular level to provide superior EMI protection. These materials can be extremely efficient while remaining thin and light, which is especially important in mobile devices and wearables.

- Conductive Polymers: For electronics requiring flexible shielding (such as wearable tech or bendable screens), conductive polymers offer a promising alternative. They are not only lightweight and flexible but also capable of offering robust EMI protection.

- Metal-Organic Frameworks (MOFs): While still in the research phase, MOFs have shown great potential in providing lightweight EMI shielding with the added benefit of being environmentally friendly. These porous materials can be adjusted to various frequencies, offering tailored protection.

- Challenges: While these materials show great promise, their cost, manufacturing scalability, and performance consistency still need to be fine-tuned before they can be implemented in mainstream applications.

Growing Importance of EMI in 5G and IoT

As we enter the 5G era and the age of the Internet of Things (IoT), EMI management is becoming more critical than ever. Here’s why:

- 5G Networks: The deployment of 5G networks is set to bring ultra-fast wireless communication, but it will also bring along the challenge of managing higher frequencies (millimeter waves) that are more susceptible to EMI. These high-frequency signals can easily be disrupted by both natural sources and electronic devices, so shielding and filtering will play a key role in ensuring the reliable performance of 5G infrastructure.

- IoT Devices: With billions of IoT devices (everything from smart thermostats to industrial sensors) expected to be in operation, managing EMI in this vast network will be essential. These devices must be shielded from each other and from environmental interference to avoid signal degradation and device malfunctions. As more smart cities and smart homes become a reality, the EMI burden will increase significantly, demanding more robust shielding and interference mitigation techniques.

- Challenges: The sheer volume of devices and the increased frequency range will create a challenge for designers. Efficient EMI filtering, shielding, and testing protocols will need to be adapted to handle the new levels of complexity that 5G and IoT will introduce.

Artificial Intelligence (AI) and Machine Learning in EMI Testing and Optimization

Another exciting development in EMI management is the use of artificial intelligence (AI) and machine learning to optimize EMI testing and shielding design.

- AI-based EMI Prediction: Machine learning algorithms can analyze complex patterns of EMI data, predicting areas of high susceptibility to interference. This allows engineers to design products that can better resist EMI from the outset, saving time and money in the prototyping and testing stages.

- Automated Testing: AI-powered automated EMI testing systems can run tests continuously, analyzing results in real-time and adjusting shielding strategies on the fly. This makes the testing process much faster and more efficient, especially for large-scale product development.

- Optimization of Shielding Designs: AI can also help optimize shielding materials and designs. For instance, AI can simulate the behavior of various shielding materials under different electromagnetic conditions and suggest the best configuration based on factors like cost, weight, and performance.

- Challenges: The integration of AI into EMI management processes will require significant investment in both research and infrastructure. Additionally, the accuracy of AI predictions relies on having large amounts of data to train the algorithms, which may not always be available in all industries.

The Ongoing Need for EMI Testing and Compliance

As technology continues to advance, the need for EMI testing and ensuring EMI compliance becomes more important. Regulatory bodies across the world, such as the FCC (Federal Communications Commission) in the U.S. and CE (Conformité Européenne) in Europe, have set stringent guidelines to control the amount of electromagnetic emissions devices can generate. These regulations are not just about maintaining product performance, but also about ensuring safety, particularly in industries like medical devices, aviation, and automotive systems.

Why EMI Testing Will Always Matter:

- Consumer Safety: Devices that fail to meet EMI standards can cause interference with other equipment, leading to safety hazards. For example, interference in pacemakers or automotive systems could have life-threatening consequences.

- Product Reliability: Consistent EMI testing ensures that products function as intended, free from disruptions caused by electromagnetic noise. This is crucial for industries like telecommunications, automotive, and defense.

- Regulatory Compliance: Companies need to meet EMI compliance standards to avoid fines, product recalls, or litigation. Regular testing helps ensure that products meet both local and international regulatory standards, opening the doors for global market access.

The Evolving Landscape of EMI and Why It’s So Important

In the rapidly advancing world of technology, EMI management will continue to be an integral part of design, development, and product safety. EMI isn’t something that can be ignored—it’s a factor that engineers and product designers must account for at every stage of development. From consumer electronics to medical devices, automotive systems, and defense applications, managing EMI is vital for ensuring reliability, safety, and performance.

Looking ahead, the future of EMI management is bound to be shaped by new materials, innovative technologies like AI, and the challenges posed by next-gen communication systems like 5G and IoT. As the world becomes more connected and automated, EMI control will only grow in importance.

So, the next time you use your smartphone, drive your car, or see the latest medical technology in action, remember that EMI plays a crucial role behind the scenes in keeping everything running smoothly. And as EMI testing and shielding continue to evolve, so too will the technology that helps shape our lives.