Ever had your Wi-Fi go haywire when a microwave is running? Or noticed static noise on speakers near your phone? That’s electromagnetic interference (EMI) wreaking havoc. It’s an invisible troublemaker that messes with electronics, causing performance issues or even complete failures. That’s where EMI filters come in, acting like gatekeepers to block or reduce unwanted noise.

What Is EMI and Why Is It a Problem?

EMI is the unwanted noise that disrupts the performance of electronic devices. Think of it as trying to have a conversation at a concert—uninvited noise drowns out your voice. EMI comes from two main sources:

- Natural sources: Lightning strikes, solar flares, and even the Earth’s magnetic field.

- Man-made sources: Power lines, mobile phones, appliances, and industrial machinery.

The impact? Devices misbehave, communication lines break down, and sensitive equipment—like medical devices—might fail. EMI is no laughing matter when you consider that a pacemaker or airplane navigation system could be affected.

What Are EMI Filters?

Enter EMI filters, the unsung heroes of electronic systems. These filters are designed to suppress or block unwanted interference. They’re a mix of electronic components that work together to remove high-frequency noise while letting the desired signals pass.

Here’s a simple analogy: If EMI is background chatter in a noisy café, EMI filters are the noise-canceling headphones you put on to focus.

- Key Components: Capacitors, inductors, and sometimes resistors.

- Applications: Found in laptops, refrigerators, medical equipment, cars, and even spacecraft.

By ensuring that EMI doesn’t sneak into critical systems, these filters make sure our technology works seamlessly.

Why Are EMI Filters So Important?

Imagine a world without EMI filters. Your smartphone might freeze when you use a blender, airplanes could lose communication mid-flight, and heart monitors in hospitals might give false readings.

Here’s a list of industries where EMI filters are absolutely essential:

- Healthcare: Protecting sensitive devices like MRI machines.

- Automotive: Ensuring electronic stability controls aren’t disrupted.

- Aerospace: Preventing interference with navigation and communication systems.

- Consumer Electronics: Keeping your gadgets functional in noisy environments.

In essence, EMI filters are the quiet superheroes of modern technology.

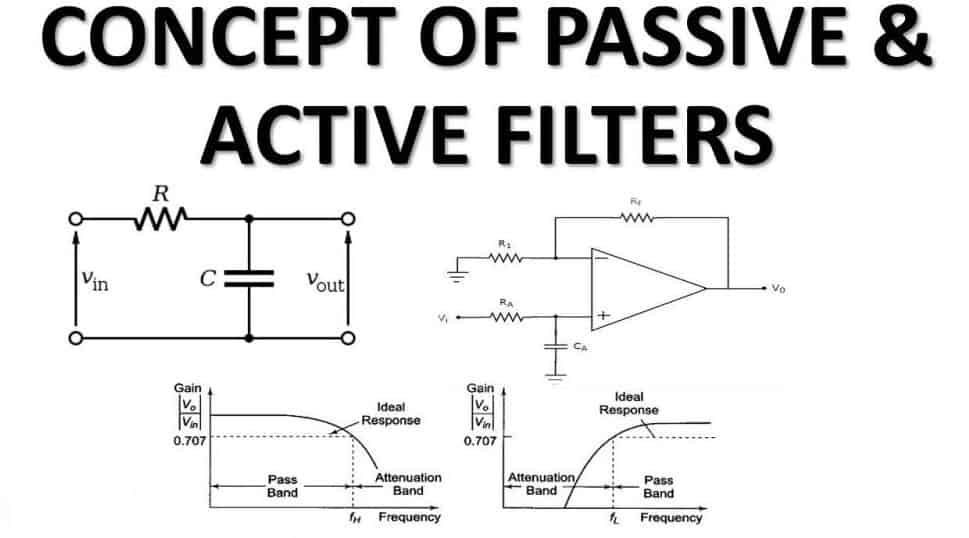

What Are Active EMI Filters?

Active EMI filters are like the tech-savvy multitaskers of the filter world. These filters use active components, such as transistors and amplifiers, to actively monitor and cancel out electromagnetic interference. Instead of just blocking noise, they fight fire with fire by injecting counteracting signals to neutralize unwanted frequencies.

Here’s how they work:

- Detection: Sensors identify the EMI signal.

- Analysis: The filter’s circuitry processes the interference.

- Neutralization: A counter-signal is generated to cancel out the EMI.

Think of active EMI filters as noise-canceling headphones. They don’t just muffle the sound; they actively counteract it.

Key Features of Active EMI Filters:

- Adaptive: They adjust dynamically to varying levels of interference.

- Compact: Typically smaller and lighter than passive filters.

- Precision: Provide highly effective noise cancellation over a broad frequency range.

But it’s not all sunshine and rainbows. Active filters have their quirks:

- Power Dependency: They need a power source to function, which might not be ideal for all setups.

- Complexity: More components mean higher complexity and potential for failure.

- Cost: They’re pricier than their passive counterparts.

What Are Passive EMI Filters?

If active filters are the tech-savvy multitaskers, passive EMI filters are the reliable old-schoolers. They rely on passive components like capacitors, inductors, and resistors to block or divert unwanted signals. These filters work without any external power source, making them straightforward and dependable.

Here’s their process:

- Block High Frequencies: Capacitors divert high-frequency noise.

- Suppress Noise: Inductors prevent high-frequency currents from passing through.

- Simple Mechanism: No fancy tricks—just solid engineering.

Passive filters are like earplugs at a concert: they reduce the noise by filtering it out.

Key Features of Passive EMI Filters:

- Simplicity: Fewer moving parts mean less can go wrong.

- Durability: They last longer with minimal maintenance.

- Cost-Effective: Affordable for mass production and widespread use.

- Power-Free: They don’t rely on external power, which is a big plus in energy-conscious setups.

However, passive filters come with their own limitations:

- Bulky Size: Especially in low-frequency applications, they can be physically large.

- Less Adaptable: Not as effective for dynamic or high-frequency interference.

- Performance Trade-offs: Less precise than active filters in certain scenarios.

The Fundamental Differences Between Active and Passive EMI Filters

Here’s a side-by-side comparison to summarize their differences:

| Feature | Active EMI Filters | Passive EMI Filters |

|---|---|---|

| Components | Active (amplifiers, transistors) | Passive (capacitors, inductors) |

| Power Requirement | Requires external power | No external power needed |

| Performance | High precision, adaptable | Simple, reliable, but less precise |

| Size | Compact | Bulky |

| Cost | More expensive | Cost-effective |

| Applications | High-tech systems, aerospace, medical | Consumer electronics, industrial setups |

When to Choose Active or Passive EMI Filters

- Active EMI Filters: Ideal for high-tech applications requiring adaptability, such as data centers, aerospace systems, and medical devices. They shine in environments with fluctuating EMI levels or when compact solutions are needed.

- Passive EMI Filters: Perfect for simple, low-maintenance setups like home appliances or industrial machinery. They’re the go-to choice for cost-sensitive projects with stable interference levels.

By understanding these differences, you’re one step closer to choosing the right EMI filter for your specific needs.

Advantages and Disadvantages of Each Type

Pros and Cons of Active EMI Filters

Active EMI filters are advanced tools with several strengths, but like any technology, they also come with trade-offs. Let’s break it down:

Advantages

- High Performance: Active filters excel in dynamic environments where interference levels fluctuate. They can adapt and maintain effectiveness across a wide frequency range.

- Compact Design: Thanks to modern technology, active filters are generally smaller and lighter than their passive counterparts, making them a preferred choice for portable or space-constrained applications.

- Precision: They offer superior noise cancellation, especially in applications requiring low noise floors or precise signal integrity (e.g., medical devices or data centers).

- Customizability: Engineers can tweak active filters to handle specific types of EMI, making them highly versatile.

Disadvantages

- Power Dependency: Active filters need a continuous power source to operate. This dependency could be a limitation in energy-sensitive systems or remote locations.

- Higher Cost: The complexity of active components, such as amplifiers and microcontrollers, makes these filters more expensive to produce and maintain.

- Complexity: More parts mean more potential failure points. Diagnosing and repairing an active filter can be challenging compared to a simpler passive design.

Example: A hospital using MRI machines benefits greatly from active EMI filters, as they ensure that the imaging equipment remains accurate, even in an environment filled with other electronic devices.

Pros and Cons of Passive EMI Filters

Passive EMI filters are the no-frills workhorses of the EMI world. Their simplicity is both their greatest strength and their most significant limitation.

Advantages

- Cost-Effective: Passive filters are affordable, making them a go-to choice for mass-market products and industries with tight budgets.

- Durable and Reliable: With fewer components, passive filters are less likely to fail. They can often run for years without maintenance.

- Power Independence: They don’t require external power, which is ideal for energy-saving systems or remote setups.

- Simple to Implement: Easy to design, install, and integrate into existing systems.

Disadvantages

- Size: To filter out low-frequency noise, passive EMI filters can become physically large, which may not be suitable for compact devices.

- Limited Adaptability: Passive filters can’t adjust to changing EMI conditions, making them less effective in dynamic environments.

- Performance Limitations: They’re less precise than active filters, particularly when dealing with high-frequency interference.

Example: A refrigerator or washing machine often uses passive EMI filters to ensure that electrical noise from the motor doesn’t interfere with nearby electronics.

Active vs. Passive EMI Filters

Here’s a brief rundown of the pros and cons:

| Type | Advantages | Disadvantages |

|---|---|---|

| Active | High precision, compact, adaptable | Expensive, power-dependent, complex |

| Passive | Affordable, durable, power-free | Bulky, less adaptable, performance trade-offs |

Why Knowing the Pros and Cons Matters

Choosing the right EMI filter isn’t just a matter of preference—it can make or break the performance of your electronic system. If you’re developing a high-tech device that requires precision, active EMI filters might be the way to go. For simpler applications with a focus on cost and durability, passive EMI filters are likely your best bet.

How to Choose the Right EMI Filter

Factors to Consider When Choosing an EMI Filter

Choosing between active and passive EMI filters isn’t just a technical decision; it’s about matching the right tool to the job. Here are some key factors to consider:

- Application Requirements

- What kind of system are you designing or troubleshooting?

- For high-performance systems (e.g., medical imaging, telecommunications), active EMI filters are often the better choice.

- For general-purpose devices (e.g., appliances, industrial machines), passive filters typically suffice.

- Budget Constraints

- Active EMI filters, with their advanced components, are pricier to manufacture and maintain. If cost is a limiting factor, passive filters are more economical.

- Power Availability

- Active filters require a stable power supply to function. If your system operates in a remote or energy-sensitive environment, passive filters might be the only viable option.

- Size and Space

- Compact systems benefit from active filters due to their smaller form factor. Conversely, passive filters may require more physical space, particularly for low-frequency applications.

- Frequency Range and Noise Levels

- If your system experiences high-frequency or highly variable EMI, active filters offer superior adaptability. For consistent, low-frequency noise, passive filters perform reliably.

Active or Passive? Making the Right Choice

To simplify your decision-making process, consider these scenarios:

- When to Choose Active EMI Filters:

- You need high precision and adaptability.

- Your system operates in a noisy, high-frequency environment with fluctuating EMI levels.

- Space is limited, and a compact solution is preferred.

- Examples: Aerospace systems, sensitive medical equipment, high-end data centers.

- When to Choose Passive EMI Filters:

- Your priority is cost-effectiveness and simplicity.

- The system operates in a stable environment with predictable EMI levels.

- Power independence is critical.

- Examples: Home appliances, industrial motors, basic electronic systems.

Consulting with Experts

Still unsure? Consulting with an EMI specialist or engineer can be a game-changer. Here’s why:

- They can analyze your system’s unique EMI challenges and recommend tailored solutions.

- They have access to advanced diagnostic tools to measure and evaluate interference levels.

- They can help you navigate technical standards and compliance requirements, like FCC or CE certifications.

Pro Tip: Investing in a well-matched EMI filter upfront can save you from costly redesigns, unexpected downtime, or compliance issues down the road.

Choosing the right EMI filter is about balancing performance, cost, and practicality. Think of it like choosing the right shoes: sneakers for running, boots for hiking, and sandals for the beach. Picking the wrong filter can lead to inefficiencies, over-engineering, or worse—system failure.

Armed with these considerations, you’re now equipped to make a smart choice tailored to your system’s needs.