Electronics rule our lives, but with every convenience comes its unruly cousin: interference. Electromagnetic Interference (EMI) can wreak havoc on devices, making them act like rebellious teens refusing to follow commands. And then there’s Electromagnetic Compatibility (EMC), the art of ensuring devices play nice together without stepping on each other’s signals.

Reducing EMI and achieving EMC is more than a compliance checkbox; it’s about creating reliable, safe, and efficient designs.

Imagine your peaceful neighborhood disrupted by a neighbor blasting heavy metal at 2 AM. That’s EMI in the world of electronics: an unwanted electrical noise or signal disrupting the harmonious operation of devices.

There are two main types of EMI:

- Conducted EMI: Travels through cables, power lines, or circuit traces.

- Radiated EMI: Travels through the air as electromagnetic waves.

Common Sources of EMI:

- Power Supplies: Switching regulators can be noisy.

- Motors: Ever noticed interference when a blender or hairdryer is on? Blame the motor!

- Antennas: Devices with poor shielding can unintentionally radiate signals.

Fun Fact: In 1936, EMI from an electric tram reportedly disrupted the BBC’s live broadcast, proving EMI issues aren’t new—they’ve just evolved with technology!

What is EMC?

EMC ensures your devices work together in harmony—like an orchestra where each instrument (device) contributes without drowning out the others. It’s about enabling a device to function without emitting harmful interference or being overly sensitive to external interference.

The relationship between EMI and EMC is straightforward: reduce EMI, and you’re halfway to achieving EMC. EMC isn’t just technical jargon; it’s a vital part of electronics design, ensuring everything from your Wi-Fi to your pacemaker works seamlessly.

Why It Matters:

- Avoid system malfunctions.

- Prevent safety hazards.

- Comply with international standards.

Causes of EMI

To tackle EMI, you first need to know where it comes from. EMI doesn’t pop out of nowhere; it’s often a product of modern technology running wild. Let’s break it down into natural and man-made sources to get a clear picture.

Natural Sources of EMI

Sometimes, nature throws its own electromagnetic tantrums. Here are a few culprits:

- Atmospheric Conditions: Lightning storms can generate massive electromagnetic pulses (EMPs), causing disruptions to power lines and communication systems. Imagine trying to tune your radio during a thunderstorm—it’s like static on steroids.

- Solar Activity: Solar flares and geomagnetic storms can disrupt satellite communications and GPS systems. These cosmic events are rare but have a significant impact when they strike.

- Cosmic Noise: The universe isn’t exactly quiet. Celestial objects like stars emit electromagnetic waves, which can interfere with sensitive instruments like radio telescopes.

Quick Example: In 1989, a geomagnetic storm caused a massive power outage in Quebec, Canada. The culprit? Solar activity wreaking havoc on the electrical grid.

Man-Made Sources of EMI

Most EMI issues, however, come from us humans—and our love for gadgets. Here’s a list of common offenders:

- Industrial Equipment: High-power machinery, like welding machines and motors, can produce EMI, disrupting nearby devices.

- Consumer Electronics: Ever noticed the buzzing sound from speakers when your smartphone is too close? Devices like microwaves, mobile phones, and even LED lights can radiate EMI.

- Wireless Communication Systems: With a growing number of wireless devices, from routers to Bluetooth headphones, the spectrum gets crowded. Poorly designed devices can emit unwanted signals.

- Switching Power Supplies: These are compact and efficient but notorious for high-frequency noise that can creep into circuits.

Common Scenarios Where EMI Becomes a Problem

EMI isn’t just annoying; it can be downright dangerous. Here are some real-world scenarios where EMI can cause havoc:

- Medical Equipment: Imagine a pacemaker malfunctioning due to interference from nearby devices. Lives could be at risk.

- Automotive Systems: Modern vehicles rely on sensors and electronic control units (ECUs). EMI can disrupt these systems, leading to performance issues or safety hazards.

- Aerospace and Military Applications: Aircraft and defense systems operate in high-EMI environments. Failing to address interference could compromise mission-critical operations.

Case Study: In 2003, an EMI issue in a U.S. Navy ship’s radar system caused interference with the vessel’s navigation systems, highlighting the importance of EMI management in complex environments.

Why Understanding Causes of EMI is Crucial

Knowing the sources of EMI isn’t just for engineers—it’s a practical step for anyone working with electronics. Whether you’re designing a PCB or just trying to fix your buzzing speakers, identifying the source is the first step in mitigation.

Pro Tip: If you’re troubleshooting EMI at home, start with the basics. Turn off nearby devices one by one to isolate the culprit. It’s like playing detective, but with gadgets!

Impacts of EMI and Importance of EMC Compliance

EMI isn’t just an annoyance; it has far-reaching consequences, from minor glitches to catastrophic failures. Whether it’s a flickering display or a life-critical system malfunction, the impacts of EMI are felt across industries.

Effects of EMI on Devices

EMI’s effects range from pesky disturbances to full-blown disasters. Here’s a closer look:

- Device Malfunctions:

EMI can cause devices to behave unpredictably—turning off, rebooting, or performing actions they weren’t programmed to do. Imagine a drone suddenly losing control mid-flight due to interference from nearby radio signals. - Data Loss and Corruption:

EMI can corrupt data transmissions between devices. For instance, in a factory with heavy machinery, EMI can disrupt communications between sensors and controllers, leading to errors in production lines. - Communication Disruption:

Wireless networks, radios, and cellular devices are particularly vulnerable to EMI. Dropped calls, slow internet speeds, or static-filled audio are often caused by interference. - Safety Hazards:

In critical systems—like medical devices, aviation systems, or nuclear power plants—EMI can lead to catastrophic failures, putting lives at risk.

Case Study: In 2016, an EMI issue was reported in the Tokyo Metro system, where interference from LED lighting disrupted train communication systems. Though resolved quickly, the incident underscored how even mundane sources of EMI can impact critical infrastructure.

Regulatory Standards and Testing

Why Compliance Matters

Governments and international bodies have established standards to minimize EMI and ensure devices can coexist without interference. Non-compliance can result in hefty fines, product recalls, and, most importantly, damage to your brand’s reputation.

Here’s what you need to know about EMC standards and testing:

- Global Standards:

- FCC (Federal Communications Commission): Sets EMI regulations for devices sold in the U.S.

- CISPR (International Special Committee on Radio Interference): Covers emissions limits for Europe.

- ISO (International Organization for Standardization): Provides EMC guidelines for automotive and industrial sectors.

- Testing for Compliance:

EMC testing ensures your product meets these standards before hitting the market. It’s typically divided into:- Pre-Compliance Testing: Performed early in the design cycle to catch EMI issues.

- Full Compliance Testing: Conducted in certified labs to ensure the product meets all regulatory requirements.

Key EMC Standards by Region

| Region | Standard | Applies To |

|---|---|---|

| United States | FCC Part 15 | Consumer electronics |

| Europe | EN 55032 / EN 55035 | Multimedia and IT equipment |

| Automotive | ISO 11452, CISPR 25 | Vehicle electronics |

| Medical Devices | IEC 60601-1-2 | Healthcare equipment |

Risks of Ignoring EMC Compliance

Skipping EMC compliance is like ignoring the warning lights on your car’s dashboard—trouble is inevitable. Risks include:

- Legal Penalties: Selling non-compliant products can result in bans or fines.

- Product Recalls: If your product causes interference, you may face recalls, damaging your brand’s credibility.

- Loss of Market Access: Certain regions, like the EU, won’t allow non-compliant products on the market.

- Customer Dissatisfaction: Devices prone to interference can frustrate users, leading to bad reviews and lost sales.

Pro Tip: Even if you’re designing a one-off project, understanding EMC compliance helps you create robust and reliable systems.

EMI and EMC in Everyday Life

You may not realize it, but EMI and EMC compliance affect your daily life:

- The reason your Wi-Fi router doesn’t interfere with your TV? EMC compliance.

- Why your Bluetooth headphones don’t go haywire near your microwave? Proper EMI shielding.

Addressing EMI and ensuring EMC compliance isn’t just about meeting regulations—it’s about creating better, safer, and more reliable products. It’s the foundation of building trust in your devices, whether they’re used in homes, cars, or hospitals.

How to Reduce EMI and Ensure EMC

Designing for low EMI and ensuring EMC compliance is both an art and a science. It requires a combination of smart design choices, effective shielding, and robust testing. Let’s explore actionable strategies to tackle EMI and achieve EMC.

Design-Level Strategies

The best way to address EMI is to stop it at the source. Smart design choices can significantly reduce interference and make devices EMC-friendly.

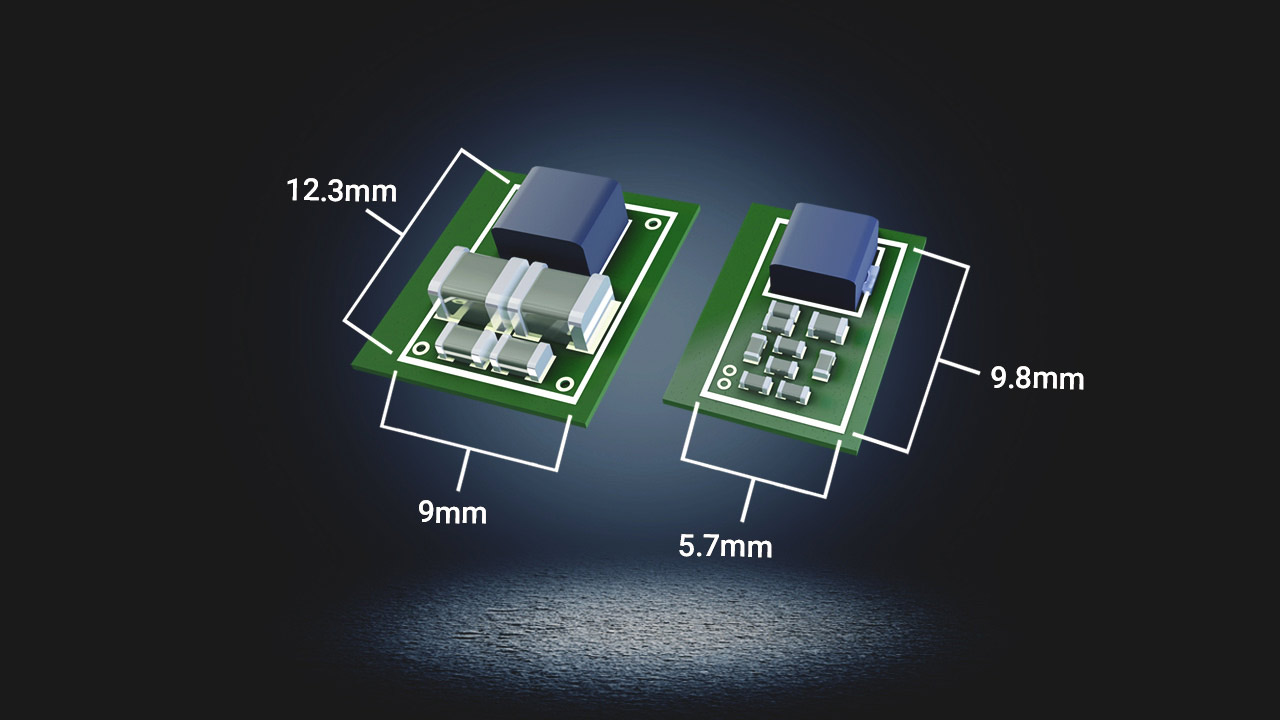

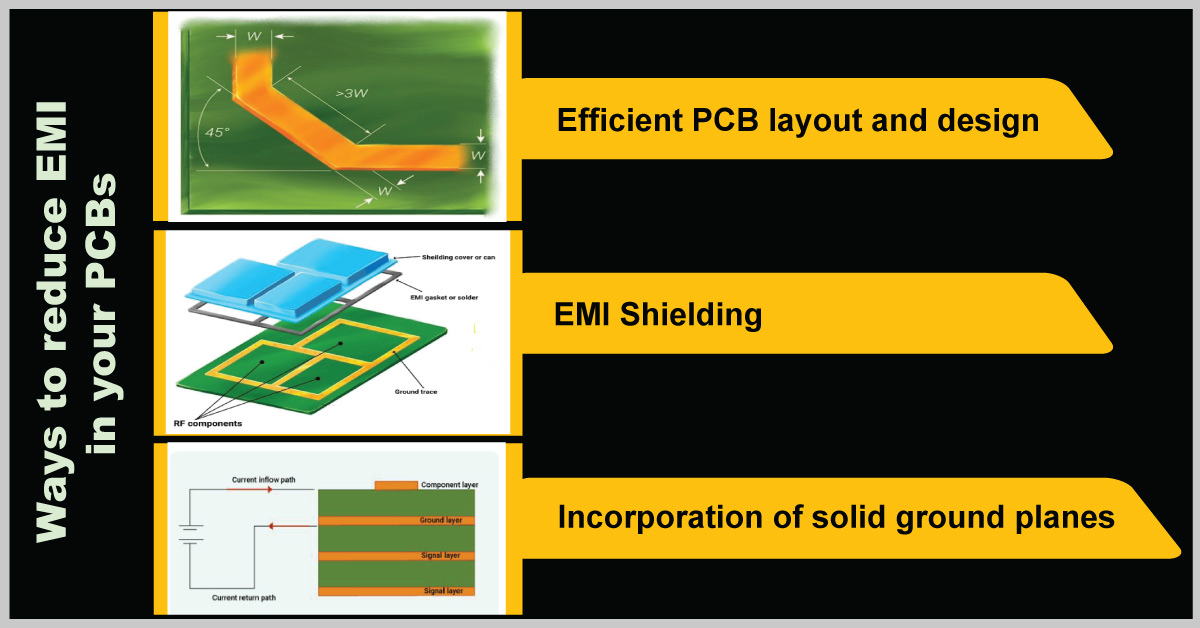

PCB Design Best Practices

The Printed Circuit Board (PCB) is the heart of any electronic device, and its design plays a crucial role in EMI reduction. Here’s how to get it right:

- Use Ground Planes:

Ground planes act as shields, absorbing unwanted noise. A continuous ground plane under high-speed signals minimizes electromagnetic radiation. - Minimize Loop Areas:

Large loops act like antennas, emitting or picking up EMI. Route return paths directly under the signal paths to reduce loop areas. - Segregate High-Speed Signals:

Keep noisy signals (e.g., clock lines) away from sensitive analog components. Use layout techniques like partitioning to avoid cross-talk. - Controlled Impedance:

For high-frequency signals, design traces with controlled impedance to avoid signal reflections and radiated noise.

Pro Tip: Use PCB simulation tools like Altium Designer or Cadence to identify potential EMI hot spots before manufacturing.

Component Selection

Choosing the right components can make a world of difference:

- Low-Noise Oscillators: Select oscillators with low phase noise to reduce EMI from clock signals.

- Shielded Inductors: Prevent magnetic coupling between inductors in power supplies.

- EMI-Suppression Ferrite Beads: Place these on power lines to block high-frequency noise.

Case Example: A team designing a wearable medical device reduced EMI by switching to shielded connectors and low-noise DC-DC converters, resulting in a 40% drop in emissions.

Shielding Techniques

When noise cannot be eliminated at the source, shielding becomes critical. Shields act as barriers, containing or blocking electromagnetic waves.

- Metal Enclosures:

Encasing devices in conductive materials like aluminum or copper prevents emissions from escaping or entering. - EMI Gaskets:

These flexible materials seal gaps in enclosures, ensuring continuous shielding even in dynamic environments. - PCB-Level Shielding:

Use shielding cans on PCBs to protect high-frequency circuits from external noise.

Testing Tip: Always measure the effectiveness of your shielding using tools like a spectrum analyzer. A poorly grounded shield can become a noise source instead of a solution.

Filtering Solutions

Filters are like noise-cancelling headphones for your circuits—they block unwanted frequencies while allowing desired signals to pass.

- EMI Filters:

- LC Filters: Use inductors and capacitors to suppress high-frequency noise.

- RC Filters: Ideal for low-frequency applications, these resistors and capacitors work well on signal lines.

- Power Line Filters:

- Place filters on power inputs to block conducted EMI from entering or leaving the device.

- Use common-mode chokes to suppress noise in differential power lines.

Real-World Example: A commercial LED driver failed EMI compliance due to noise on its power line. Adding a simple LC filter resolved the issue, saving time and cost.

Proper Grounding and Bonding

Grounding and bonding are often overlooked but are essential for reducing EMI:

- Avoid Ground Loops:

Ground loops can act as antennas, amplifying EMI. Use a star grounding system to ensure all components share a single reference point. - Bonding for High-Frequency Circuits:

Ensure metal enclosures and PCBs are bonded to a common ground to prevent radiated noise.

Quick Tip: For high-frequency circuits, mesh grounding may outperform star grounding. Analyze your design to choose the best option.

Cable Management

Cables are like highways for EMI, so managing them effectively is key:

- Use Shielded Cables:

Shielded cables prevent noise from coupling into signal lines. Ensure shields are grounded at one end to avoid ground loops. - Twist Pair Wires:

Twisted pairs reduce electromagnetic emissions by canceling noise. - Avoid Parallel Routing:

Route cables at 90-degree angles to minimize electromagnetic coupling.

Think of EMI management like organizing your sock drawer—no crisscross chaos. Neat, separated paths keep everything in order!

Effective EMI reduction starts at the design stage but also requires proper shielding, filtering, and grounding. Combining these strategies ensures your device not only meets EMC standards but also performs reliably in the real world.

Tools and Equipment for EMI and EMC Testing

Reducing EMI and achieving EMC compliance isn’t complete without thorough testing. After all, even the most meticulously designed circuits can produce unexpected interference.

Pre-Compliance Testing Tools

Pre-compliance testing helps catch EMI problems early in the design process, saving time and cost. Think of it as a dress rehearsal before the big performance. Here are the go-to tools for pre-compliance testing:

- Spectrum Analyzers

- Purpose: Measure the frequency and amplitude of electromagnetic emissions.

- Use Case: Detect and visualize unwanted signals from your device.

- Tip: Portable spectrum analyzers are ideal for quick on-site troubleshooting.

- Near-Field Probes

- Purpose: Pinpoint specific areas on a PCB or system emitting high EMI.

- Use Case: Identify problem spots like noisy traces or components.

- Pro Tip: Combine probes with an oscilloscope or spectrum analyzer for detailed analysis.

- Oscilloscopes with EMI Debugging Features

- Purpose: Capture high-speed signals and identify noise patterns.

- Use Case: Analyze timing and waveform distortions caused by EMI.

- Example: The Tektronix MDO series oscilloscope doubles as a spectrum analyzer for added functionality.

Full-Compliance Testing Equipment

Once your design passes pre-compliance tests, it’s time for the big leagues: full-compliance testing. This requires specialized equipment and certified labs to ensure adherence to international standards.

- Anechoic Chambers

- Purpose: Provide a controlled, interference-free environment for radiated EMI testing.

- Use Case: Measure emissions from devices without external noise interference.

- Fun Fact: The word “anechoic” means “without echo,” describing the chamber’s ability to absorb sound and electromagnetic waves.

- Radiated Emissions Test Setups

- Equipment: Log periodic or biconical antennas paired with EMI receivers.

- Purpose: Measure the electromagnetic energy radiated by a device.

- Use Case: Validate compliance with standards like FCC Part 15 and CISPR.

- Conducted Emissions Test Systems

- Equipment: LISNs (Line Impedance Stabilization Networks) and EMI receivers.

- Purpose: Measure noise conducted through power lines.

- Use Case: Ensure compliance with power line emission standards.

Simulation and Software Tools

Modern design workflows incorporate EM simulation tools to predict and prevent EMI issues before hardware testing. These tools are invaluable for tweaking designs without costly prototypes.

- EM Simulation Software

- Examples: Ansys HFSS, CST Studio Suite, and Keysight EMPro.

- Purpose: Simulate electromagnetic fields, signal integrity, and PCB design.

- Use Case: Model the impact of shielding, grounding, and component placement.

- SPICE Circuit Simulators

- Purpose: Analyze noise in circuit designs at the component level.

- Use Case: Simulate filter performance to fine-tune EMI suppression.

Real-World Example: A design team used Ansys HFSS to optimize shielding placement for a high-speed router, reducing radiated EMI by 30% before physical testing.

Practical Testing Tips

- Start Early: Incorporate pre-compliance testing during the prototyping phase to catch EMI issues early.

- Calibrate Equipment Regularly: Ensure test equipment provides accurate results.

- Document Everything: Maintain detailed records of test conditions, results, and changes made.

Testing for EMI is like arguing with a toddler—you never know where the next outburst will come from. Be patient, systematic, and ready for surprises!

Costs and Accessibility

Budget-Friendly Options: If full-compliance testing seems out of reach, invest in pre-compliance tools and rent lab time for final certification. Many EMI test facilities offer hourly rentals, including access to expert consultants.

DIY Enthusiasts: Building a makeshift Faraday cage or using inexpensive near-field probes can help hobbyists troubleshoot EMI issues at home.

Whether you’re an industry professional or a tinkerer, having the right tools for EMI and EMC testing is crucial. Pre-compliance tools, full-compliance facilities, and modern simulation software form a robust testing toolkit that ensures your devices are reliable, compliant, and ready for the market.